2022.11.24 Crusher production capacity is defined as the volume of material that a crusher can crush per unit of time, which is an important indicator of crusher performance . According to the lamination crushing

Read More

2017.5.1 Introduction In a comminution plant where the reduction of rock material or ore sizes is desired, two machines are commonly used for primary crushing: the jaw

Read More

2020.9.20 The 2S crushing consisted of primary and secondary crushers as Jaw and HSI (horizontal shaft impactor), respectively, while 3S crushing was composed of primary, secondary and tertiary crushers as ...

Read More

2022.5.13 2 Concept of Stone Crusher Stone Crusher is a sort of pulverizer which is utilized to compress or break out

Read More

The capacity of a jaw crusher is given by the amount of crushed material passing the discharge opening per unit time. This is dependent on the area of the discharge opening,

Read More

2022.9.20 The suitability of a jaw crusher is determined by its capacity, reliability, durability, versatility, minimal maintenance requirements, and ease of replacing worn-out

Read More

Jaw crushers are probably easily recognized crusher in size reduction operation. The reduction ratio of jaw crusher is 3:1 to 5:1. This paper focuses on review of a work done

Read More

2019.1.1 Crusher choice primarily relies on material size, the desired end product, operating costs, and environmental considerations [11]. A two-crushing process can be

Read More

In addition to the CSS, Johansson et al. [17] introduced a model for the evaluation of jaw crusher capacity and power draw in connection with various jaw speeds. ...

Read More

421955a1 — chengxinjia sbm a month ago. View Rendered; View Source

Read More

2023.9.5 stone line topic. Details of limestone gravel production line with 500-550 tons per hour ... Compared with traditional jaw crusher, JC series jaw crushers pays more attention on details in the process of design and manufacture. ... Capacity. 50-2700t/h. Max feeding size. 2100mm. Raw materials. River stone, gravel, granite, basalt, minerals ...

Read More

2022.12.24 A dynamic model of the working mechanism of a compound pendulum jaw crusher with clearance is established by the Lagrange multiplier method (LMD) based on the L-N contact force model

Read More

颚式研磨仪应用领域. A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials. The RETSCH jaw crusher range is primarily used in laboratories and pilot plants under rough conditions but are also suitable for on-line quality control of raw materials. The main fields of ...

Read More

2023.2.28 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes. Each stage uses different types of crushers and has distinct advantages and disadvantages. This article provides a comprehensive guide to primary, secondary, and tertiary crushing.

Read More

2019.1.1 Particle size distribution curves of recycled aggregates from building demolition concrete crushed by jaw and impact crushers. The jaw crusher produced 60% of coarse aggregates in weight, whereas the impact crusher produced 49% coarse aggregates. The proportion of particles finer than 0.15 mm is around 7–8% weight for both crushing

Read More

Contribute to yunan88/crusher development by creating an account on GitHub.

Read More

2021.4.12 The rock breaks and falls out the bottom. These types of crushers are usually applied as tertiary or quaternary crushers with less than 2” (75 mm) feed or smaller. Some Vertical Shaft Impactors can be used as secondary crushers with larger feed. Vertical Shaft Impactors are very application-specific. They are sensitive to abrasive materials ...

Read More

2020.2.8 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle size affect the products of the cone of the crusher (its cumulative weight fraction). The CSS,

Read More

2023.10.16 The ore coming from the quarry is passed from the grid with a clearance of 150 mm and the material above a grain size of 150 mm are conveyed to jaw crusher with a capacity of 400 tonne/h. This ...

Read More

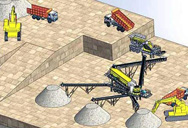

Published Feb 3, 2023. + Follow. In a typical crushing plant, the following machines are commonly used: Jaw Crusher: A jaw crusher is used for primary crushing. It uses compressive force to crush ...

Read More

2020.6.1 Product quality is measured in terms of particle shape and mechanical properties. The crusher and feed parameters used are closed side setting (CSS), speed, feed rate and feed gradation. This paper presents a parameter study investigating the effect of feed and jaw crusher parameters on the quality of aggregates produced from single

Read More

2017.8.27 jaw crusher Concrete floor G-7 G-4 Fig. 1.Building housing primary-crushing unit. a) section; b) foundation of SMD-60A jaw crusher; c) settlement curves of column foun-dations in axes G-4 and G-7. Dynamic load Indicators harmonic pulse Peak force, kN horizontal vertical 116 138 3500-Frequency of force effect, Hz 2.08 60 Distance

Read More

2021.12.1 This content was downloaded from IP address 181.214.189.96 on 25/12/2021 at 00:39

Read More

2023.6.21 The moving jaw rotates around the eccentric axis as well as swings around the same center (Fig. 2).By removing the moving jaw suspension shaft and the front toggle plate of simple pendulum jaw crusher, and suspending the moving jaw on eccentric shaft to combine the connecting rod and the moving jaw into whole, a compound pendulum jaw

Read More

2022.2.14 Features: Hammer crusher crushes various stones, one-time molding, no secondary crushing and shaping process, can reduce the cost by about 40%, low energy consumption, low cost; The high-quality steel plate welded frame avoids casting defects, more firm and reliable, and ensures the quality of the machine;

Read More

2021.12.3 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the ...

Read More

2022.2.24 Stone crushing is an important part in mining industry and require high quality stone crushing machines. Nigeria Jaw Crusher - Large or Small Scale For Your Choice ... the capacity range of this new style jaw crusher is from 110-650 tons per hour. It not only can be used for large production scale, but also can meet different production ...

Read More

2015.5.13 geometry, crusher dynamics and rock material characteristics. Concave, mantle, eccentricity and location of the pivot point together form the chamber. resulting motion of the mantle and main shaft ...

Read More

2017.5.1 The throughput of a jaw crusher ranges between 30 and 1200 tph (Wills and Napier-Munn, 2015). Jaw crushers have been modelled previously; in 1953, Gauldie conducted a performance study of the jaw crusher, including a capacity model that handles varying speeds and closed side setting (CSS) (Gauldie, 1953).

Read More